In the workplace, organisations are required to manage hazards and risks by putting the appropriate control measures in place. Legally, under WHS Regulations, "risks must be controlled by eliminating them so far as reasonably practicable, or if this is not possible, reducing the risks that remain so far as reasonably practicable" (Source: WorkSafe Australia). This means that health and safety managers, or anyone who is responsible for making sure a business is in compliance with these regulations, must determine what is reasonably practicable to protect people from harm.

Before implementing control measures, hazards should have already been identified followed by conducting risk assessments as needed, so there will be a clear understanding of what hazards exist as well as the potential severity of the harm they could inflict. This knowledge will be vital when determining what controls are most reasonable and most effective.

Before implementing control measures, hazards should have already been identified followed by conducting risk assessments as needed, so there will be a clear understanding of what hazards exist as well as the potential severity of the harm they could inflict. This knowledge will be vital when determining what controls are most reasonable and most effective.

Ultimately, the decision to eliminate or reduce a hazard and the most appropriate control measures to put in place are judgement calls about what is reasonable in certain circumstances. Especially given the impact of COVID-19 and the extra layer of concern it brings to the workplace, it's especially critical to be questioning and reviewing your existing hazards, risks and control measures.

Here are 3 questions that will help you determine the best course of action:

-

What hazards and risks need to be prioritised or controlled in a timely manner?

When assessing risks in your workplace, you will have determined the likelihood of a hazard or risk occurring and the level of harm that could be inflicted. Knowing these two factors will help you determine what hazards or risks need to be controlled immediately as well as how effective a control measure needs to be. For example, a hazard that is certain to occur and could impose severe harm should be controlled immediately and, if possible, eliminated. This is where the next consideration comes in.

-

What are the options for control?

Where possible, you should always try to remove or eliminate a potential hazard or risk from the workplace. This could mean using a different process or changing the way something is done. For instance, you could use cordless or battery operated equipment instead of using extension leads or equipment with cords, which would eliminate the potential for trip hazards.

If this isn't possible, you must determine the next most effective way to minimise the risk. Use your knowledge of the hazard or risk, especially the sequence of events that could lead to the hazard imposing harm, to outline the availability and suitability of ways it could be reduced.

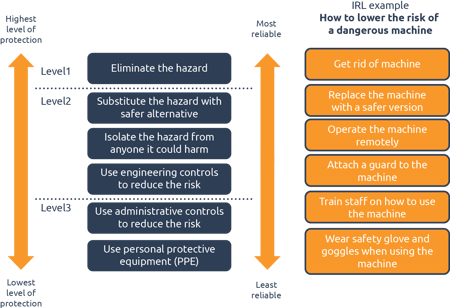

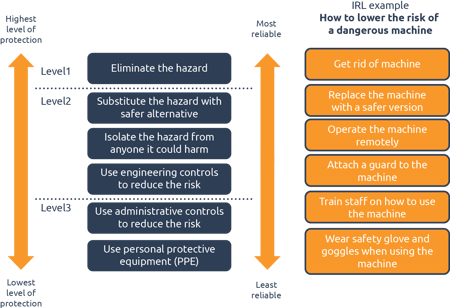

Here you'll also want to factor in the cost associated with eliminating or reducing the hazard or risk. The hierarchy of risk control (below) captures the various ways of controlling risk, ranking their effectiveness, which will be touched on in the following consideration. The three main options are:

- Eliminating the hazards or risks (level 1)

- Changing the risks to reduce them (level 2)

- Changing people to reduce the risk (level 3)

Note, too, that a control option may be a single control or it may be comprised of a number of controls the provide protection against the risk.

3. What is the most effective control option(s) based on the circumstances?

As depicted in the hierarchy of risk control, the most effective control measures are ranked from level 1 to level 3, with level 1 (eliminating the risk) being the most effective and level 3 (changing the way people behave or their exposure to the risk to reduce it) being the least effective.

This ranking is based on what control measures offer the highest level of protection and the most reliability. Essentially, if you're not able to eliminate a hazard or risk, then you want to aim to change the risk to reduce the likelihood and/or level of harm. For example, there may be a ledge on the second story of a construction site that a worker could fall from and seriously injure themselves. While it's not possible to eliminate work that has to be done on the second story, guardrails could be put up to reduce the risk of falling.

Relying on human behaviour or skill levels offer the least amount of protection and reliability. Referring to the ledge example, instructing workers to not perform work near the ledge can't guarantee that they will act accordingly. Therefore when determining the most effective control measure, changing people should be your last resort or only serve as an interim control measure or back-up control measure.

You can also refer to information from industry associations, unions, manufacturers and suppliers, among others, as there's a good chance they will be provide sound guidance on what controls to put in place. By doing this process, you will be able to identify the controls that will provide the highest level of protection that are reasonably practicable in the given circumstances and be in the position to move forward with implementation, creating a safer and healthier workplace for your employees.

If you'd like assistance with managing your WHS risks, RiskWare's Health & Safety Management Module is a single integrated system that can help give you the peace of mind you are complying with WHS regulations, protecting your people and your business.

To learn more about how RiskWare is making the world a little less risky, visit us at RiskWare.com.au.

Before implementing control measures, hazards should have already been identified followed by conducting

Before implementing control measures, hazards should have already been identified followed by conducting